Once the required demand torque in a particular application has been determined, the tendency is to determine motor power using the standard equation: kW = Nm x r/min / 9550. However, gearbox efficiency must also be considered in calculations, and is often overlooked.

Gear type, bearing type, seal type and lubrication all contribute to the inefficiency of gearboxes. As gearboxes lose efficiency, so the input power required also increases to compensate, to deliver the required torque at the output.

The type of gear primarily determines how efficient a particular gearbox is going to be. Inefficiency per stage can amount to:

Helical gears – 0.5% to 3%

Bevel gears – 0.5% to 3%

Hypoid gears – 2% to 10%

Planet gears – 2% to 10%

Crossed helical gears – 5% to 50%

Cylindrical worm gears – 10% to 50%

Spiroid gears – 3% to 50%

Worm gearboxes are renowned for having the possibility of a high ratio in a small form factor, but also having a relatively low efficiency. As a result, consideration must always be given to application demand torque.

With multiple stage units, inefficiency per stage is compounded.

With gearbox type being the key determining factor in finding efficiency, bearings and seals have a slightly smaller contribution and usually are not able to be changed for each gearbox type.

In bigger design applications, losses for bearings and seals are obviously less of a concern when compared with smaller applications.

Lubrication type (grease or oil), viscosity, and amount also contributes to gearbox inefficiency, although, like bearings and seals, are only a secondary consideration to gearbox type.

The main thing to think about when looking at gearbox application design is the overall power loss from design inefficiency, and to compensate accordingly. Planetary, inline helical and bevel helical gearboxes are the most efficient, whereas worm gearboxes are usually the least efficient.

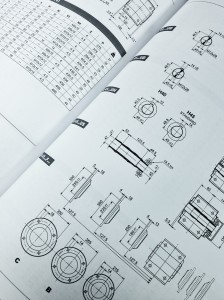

Many times we are asked to source a modern alternative to a superseded or obsolete piece of mechanical power transmission equipment.

With many brands having fallen by the wayside as the generations pass, it is our job to source a modern equivalent to a gearbox that is no longer available. Sourcing the correct replacement, paying attention to shaft size, footprint, shaft centre height, service factor and limiting speed will usually bring about a suitable equivalent from an alternative manufacturer. This is not the case in 100% of applications.

Output shafts can be adapted, especially where couplings are direct drive media are the driven component. These can obviously be adapted with machining or taper bushes to suit the required size of the current unit, which also has the added bonus of keeping the new unit standard for future replacement.

Modifying the footprint, either with direct machining or by the use of an adaptor plate, are also employed to make sure that modern gearboxes will be able to be used in any application.

Modifying the footprint, either with direct machining or by the use of an adaptor plate, are also employed to make sure that modern gearboxes will be able to be used in any application.

All Torque Transmissions is well placed to help when looking at the options for repair, replacement or retrofit. We understand the torque requirements of drive applications and are ready to assist for older units that are no longer available.

October 3rd and 4th saw the Melbourne Convention and Exhibition Centre host Waste Expo 2018.

Waste Expo showcases the latest in environmental resource recovery and waste disposal. Individual industry sectors include:

A major focus of Waste Expo 2018 was how Industry 4.0 is going to assist in the future, with smart technology and communication joining with the mechanical aspects of resource recovery.

Gasification, governmental policy, site transformation and wastewater recycling were all popular topics.

Compactors, balers, conveyors, agitators and mixers were all in evidence from manufacturers, with bevel-helical, shaft mount, planetary and in-line coaxial gearboxes all on display.

Bucket elevator gearbox design takes into consideration the special requirements of bucket elevators in the grain and bulk handling industry.

Bulk bucket elevators are vertical bulk materials handling equipment used in the transfer of grain and fertiliser between storage systems. There are differing styles, but the primary elevator is known as the Centrifugal Discharge Elevator. The very nature of bucket elevator design requires a relatively high speed, which creates specialist demands for the mechanical power transmission required to drive them.

Gearboxes for bucket elevator applications have certain design requirements:

Bevel-helical designs have become the preferred choice over the years, with either a wormbox or secondary bevel-helical as the gearbox used for low-speed positioning duties.