ABB Action Magazine has just been released for the first quarter 2014, and it is packed full of useful information for the Australian market.

Although the first quarter edition does not feature All Torque supply partners Baldor or Dodge in its pages, it does include information regarding the company’s continued push for efficiency as well as carbon pollution reduction.

The new ‘Action’ magazine can be viewed by following the link here.

ABB has even been named one of the worlds top 100 innovators by Thomson Reuters, thanks mostly to developments in the electrical side of their business.

All Torque is proud of our association with a company held in such high regard globally, and look to continue to supply their innovative products to the Australian market.

CB Series wrap spring clutch/brake combinations are designed for applications requiring a continuous rotational input being converted into starting and stopping a load. To start motion, the solenoid is pulsed, moving the actuator arm away from the control collar. This allows the clutch spring to wrap (wind) down onto the output assembly while the brake spring is unwinding, allowing the output to drive.

Motion is stopped when the actuator returns to its rest position and the control collar rotates, stopping against the actuator. This forces the clutch wrap spring to unwind releasing the input from the output and wraps the brake spring down, stopping the output. Anti-back and anti-overrun springs maintain position accuracy by eliminating any backward movement or bounce when stopped.

Motion is stopped when the actuator returns to its rest position and the control collar rotates, stopping against the actuator. This forces the clutch wrap spring to unwind releasing the input from the output and wraps the brake spring down, stopping the output. Anti-back and anti-overrun springs maintain position accuracy by eliminating any backward movement or bounce when stopped.

The actual stopping position of wrap spring clutches can be adjusted after installation by moving the splined cam of the control collar assembly.

Stop Position Accuracy ・}1/2°

Adjustable Output Stop Positions

Standard Features of Wrap Springs

– CW or CCW Rotation

– Hub Input – Shaft Output

– Anti-Overrun Output does not overrun Input

– Anti-Back Output does not Backup

1, 2 and 4 stop collars for 360°, 180°, and 90° output increments standard

– Special multi-stop collars also available (up to 24 stops)

115 VAC and 24 VDC Solenoids Standard

– Other Voltages Available

Dimensionally Interchangeable with Competitive Units

5 Standard Wrap Spring Models

* CB-2

* CB-4

* CB-5

* CB-6

* CB-8

* CB-10

Recently, a client of ours in the pulp and paper industry had a Radicon BU400 underdriven worm gearbox fail on them. The Radicon unit was on an important piece of machinery, and the failure proved to be quite costly in terms of production lost. We were given the task of making sure that a failure such as this would not happen again.![]()

On a very tight schedule, we inspected the Radicon unit with a view to an urgent repair. Existing machine hardware required that this unit be returned to service, as size and design restrictions meant that no replacement would be suitable. Immediately upon inspection, we found that the wormwheel had failed. This in turn necessitated new bearings and seals, which are a standard part of a repair anyway.

The original failure had been caused by the lubricant being separated from the wormwheel and wormshaft, increasing heat (and wear) from metal to metal contact. Eventually, the heat build-up caused heavy pitting on the teeth of the wormwheel, necessitating replacement.

Lead times for replacement spare parts for this equipment are always very long (over three months), as all stock is made to order in the UK. Obviously, this would not do on this occasion, so we took matters into our own hands.

In addition to commissioning the manufacture of a new wormwheel, we designed and fabricated an application-specific oil deflector, to ensure that lubricant remains where it should during operation.

![]() The deflector was fabricated from a single piece of aluminium plate to ensure that it remained robust during operation and mounted with socket head cap screws.

The deflector was fabricated from a single piece of aluminium plate to ensure that it remained robust during operation and mounted with socket head cap screws.

Since being returned to service, the repaired BU400 hasn’t missed a step. Lubrication control is at the heart of the turnaround.

Toyota has joined Ford and Holden in completing the exodus of the car manufacturing industry from Australia. The move was widely tipped by the manufacturer itself late last year, ahead of an announcement yesterday.

Manufacturing will cease at Toyota’s Altona plant in 2017, bringing an end to all Australian car making operations.

The obvious impact will be felt by automotive component manufacturers in Victoria and South Australia, which is where the bulk of employment in the sector is positioned.

It is difficult not to be disappointed in the decision, however continued loss-making operations must always be examined for future viability. ‘Learning By Doing’ cannot be an endless mantra. Having said that, the automotive manufacturing sector was mature, and well placed to adapt new vehicle technologies as and when they came on stream. This ability will be lost forever.

Ending co-investment in a mature business sector and hoping that other ‘innovative’ industries will emerge in its place may well be the biggest case of wishful thinking of the century.

Innovation does not occur in a vacuum; infant industries are always going to require support in order to survive and grow.

We don’t know what these industries are going to be, and we don’t know how many they will employ as a positive by-product.

Hoping that they will emerge on their own is a problem.

Damian Harris

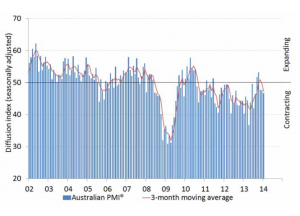

According to the Performance of Manufacturing Index (PMI) Australian manufacturing retracted for a third consecutive month in January, recording an overall figure of 46.7. The January result is a further decline from December, receding by nearly a full basis point. The PMI is conducted monthly by PriceWaterhouseCoopers and the Australian Industry Group.

Positive Results

Negative Results

Margin pressures remain high across all manufacturing sub-sectors, as input costs (including wages) continue to outstrip selling prices. As PWC / AIGroup note, this has been a feature of the Australian economy since the Global Financial Crisis in 2009.

The Australian Industry Group report for January’s PMI can be accessed here… PMI Jan 2014