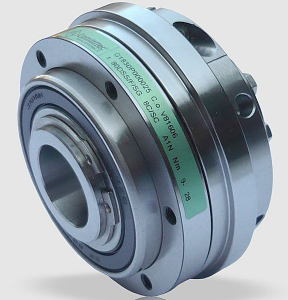

Italian torque limiter manufacturer ComInTec has just released its latest catalogue for torque limiters and clutches (edition 04/2013). The new catalogue features the full ComInTec range of limiters:

The catalogue is useful both for product identification and overload protection design, with a whole host of application information alongside technical drawings.

The catalogue is useful both for product identification and overload protection design, with a whole host of application information alongside technical drawings.

If you would like an electronic version sent right to your email, contact us and we’ll forward one immediately.

Most industrial gearbox designs are rated for continuous duty at 20°C ambient temperature.

The design manuals of geared motor manufacturers give consideration to operating conditions above and below 20°C ambient, as well as the duty cycle of the unit, and modify the thermal capacity ratings as required.

A good rule of thumb that is as old as the hills is if you can touch the unit and keep you hand on it for a few seconds without losing skin, the temperature is not a concern.

Below is a table from the Bonfiglioli A Series catalogue for bevel-helical gearboxes, identifying that 20°C ambient is the continuous duty rating, with a thermal de-rate for hotter ambient conditions and a capacity increase for lessened duties.

| Temp (°C) | Continuous Duty | Intermittent Duty | |||

| 80% | 60% | 40% | 20% | ||

| 40 | 0.80 | 1.10 | 1.30 | 1.50 | 1.60 |

| 30 | 0.85 | 1.30 | 1.50 | 1.60 | 1.80 |

| 20 | 1.00 | 1.50 | 1.60 | 1.80 | 2.00 |

| 10 | 1.15 | 1.60 | 1.80 | 2.00 | 2.30 |

This table can only be read in conjunction with the individual kW ratings of each gearbox in the range, which have a thermal rating for both 4 pole and 2 pole input speeds. The de-rate is higher for the faster 2 pole electric motor.

For probably the best, most succinct explanation of heat in industrial gearboxes, follow this link to Dr. Gerard Antony’s page which outlines how heat is caused and some of the best ways to limit its build up.

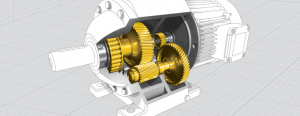

Oil technology has increased markedly over the last two decades, with synthetics becoming more and more prevalent. Gearbox manufacturers have continued to demand more from their designs as this technology evolves, allowing for even higher torque capacities from the same sized units.

The correct oil to use in industrial gearboxes is dependent on various factors, namely; the type of gearbox, individual manufacturer preferences and the duty cycle of the application, which considers the torque loadings, hours of operation and ambient conditions.

Bonfiglioli’s A Series of bevel-helical gearboxes, for example, specify a range of lubricants based on both the type of duty and the ambient conditions. For light duty at 20 degrees Celsius, they call for 150 viscosity mineral or synthetic oil. At 40 degrees Celsius they call for 220 viscosity mineral or synthetic oil. For heavy duty at 40 degrees Celsius ambient, Bonfiglioli calls for 320 viscosity synthetic and 460 viscosity mineral oil.

Wormboxes place different demands on lubrication, as they comprise brass for the wormwheel and steel for the balance of the components. Standard units in most mounting positions use a synthetic oil (Bonfiglioli specifies Shell Tivela S320 out of the factory), but an anti-foaming agent must be present as many units are ‘sealed for life’.

Many larger gear reducers are supplied unlubricated ex works, so it is important to get both the correct oil type for the application and the correct oil amount for the mounting position. Consider that gearboxes mounted vertically require more lubricant than those mounted horizontally (sometimes double the amount) so that the top bearings don’t run dry. In larger gearboxes, this can mean 50 or 60 litres of oil is required, which also carries with it substantial cost.

All Torque carries gear oil in bulk and is able to decant the amount required for individual applications.

At All Torque, there are a few ways that you can connect with us.

We have a twitter account, a facebook page, a google+ page and a LinkedIn company page.

Of course, the easiest way to get hold of us is to pick up the phone and call either Braeside (03 95872212) or Preston (03 94801566), where we are still using the technology that Alexander Graham Bell had a hand in inventing in 1876.

But, if you would like to follow our pages and get a little more insight into what makes us tick, make sure to connect.

Also, you can subscribe to our website updates via email by submitting your email address below. We hereby promise that we will NEVER spam you.

All Torque Transmissions is now keeping stock of Bonfiglioli’s latest series of electric motor, increasing the scope of supply of electric motors in both Braeside and Preston. Titled the BE series, the latest-design motor ranges from .75kW to 7.5kW initially, with stocks rising to cover up to 22kW in the coming months.

The IEC-normalized BE motors comply with IEC 60034- 30:2008 (efficiency classes) and all the applicable international standards, including the EMC and LV Directives.

Bonfiglioli BE electric motors are currently available in B5 mounting and B3 will be available shortly.

They are available in the 0.75 – 22 kW range in the foot and the flange mounting version, the latter in both the IM B5 and the IM B14 configuration.

Single pole version available with generally, two brake options offered, one DC and one AC supply, lending further flexibility to the system. Finally, all motors are inverter duty.

One of the real strengths of the Bonfiglioli electric motor range has been the quality of its brakemotors, and this is set to continue. Bonfiglioli brakemotors feature a full-length, special-purpose shaft (in opposition to some manufacturers with an extended shaft at the non-drive end) which increases the life and capacity of the standard unit.

The Bonfiglioli BE range is the perfect compliment to All Torque’s existing stable of electric motor manufacturers, with WEG’s W21 and W22 range already leaders in the field and Baldor able to manufacture any motor to order on short lead times.

The catalogue can be downloaded by clicking here.