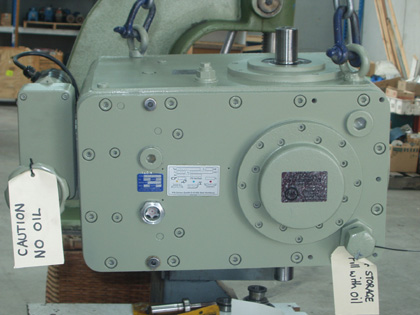

The PIV infinitely variable gear is a universally recognised device whose carefully studied design, proven operational safety and versatility make it easily adaptable to a wide variety of applications in all branches of both mechanical engineering and manufacturing industry.

The PIV infinitely variable gear is a universally recognised device whose carefully studied design, proven operational safety and versatility make it easily adaptable to a wide variety of applications in all branches of both mechanical engineering and manufacturing industry.

All Torque Transmissions supplies and services PIV gear units.

Essential elements of all PIV gears are two pairs of conical wheels which are movable on their shafts in an axial direction and are connected by a special chain. An opposite axial movement of the conical wheels will change the pitch circle of the chain and thereby the speed of the output shaft.

The system A gear has conical wheels with radial grooves and a slatted tooth chain. The laterally movable slats engage the tooth spaces of the conical wheels and transmit the adjusted torque through contact. Slip free power transmission, maximum accuracy of speed setting and good maintenance of the adjusted ratio are features of this design.

The system R gear has been developed, an in many instances higher speed and wider speed ranges as well as lower power ratings are required. The conical wheels of this type are smooth. The chain consists of cylindrical rollers, pivotably mounted on their longitudinal axes, and transmits the torque through pressure action.

All moving parts of both types of PIV gear are manufactured from high grade steel and run in an oil bath. The chain tension is maintained through an automatic re-tensioning device.

All moving parts of the gear are automatically lubricated by splash lubrication. The temperature of the gear depends on the load, the circulation of air, and the room temperature. According to the load the gears will warm up to from 40 to 70 degrees C above room temperature. The temperature of the oil should not exceed 90 degrees C. Servicing is limited to checking the oil filling and to changing the oil as required by the operating instructions. The life of the gear corresponds to that of toothed wheels and ball bearings, when working conditions are normal and servicing instructions are observed.

Aluminium production and usage is continuously trending upward the world over, as is aluminium recycling, yet Australia is having trouble employing any economies of scale to its advantage.

Australia is in a unique position when it comes to aluminium production, as we have major reserves of the bauxite which becomes alumina which becomes aluminium. State governments have seen the benefit in employment that manufacturing aluminium can bring, as well as export income, but increasingly questions are being asked about the future viability of the venture.

Making aluminium from alumina consumes a lot of energy. When they were both in operation, Victoria’s two aluminium smelters were said to represent around one quarter of the state’s electricity consumption, in a state of five and half million people. The aluminium industry is dominated by continuous base load electricity demand – in 2009 the Australian aluminium smelting industry consumed 29,250 GWh of electricity. Additionally, the amount of water used throughout the process is extremely high and with Australia only now coming out of an extended country-wide drought, questions are continuously asked as to how the precious resource is best utilised.

To give an idea of the raw numbers, estimated bauxite production in Australia was 65 million tonnes in 2009. In the same year, China produced approximately 40 million tonnes and Brazil 28 million tonnes. This contrasts markedly with actual aluminium production, with China well out on its own with 17 million tonnes, then Russia and Canada on 4 and 3 million tonnes, with Australia lagging on 2 million tonnes.

In Australia, the aluminium industry directly employs 17,000 and brings in over $8 billion of export income per annum. This is mostly in alumina or crystalline form, which is the best way to extract value from the resource.

Bauxite miners and alumina miners on the Australian continent are BHP Billiton, Rio Tinto Alcan and Alcoa of Australia. Aluminium is smeltered by Rio Tinto Alcan, Alcoa of Australia and Hydro Aluminium. Local manufacturers who are downstream from mining and smelting include companies involved in with rolled products and extrusions, such as Capral, Extrusions Australia and Ullrich.

Almost 500 jobs recently ended at Alcoa’s Geelong aluminium smelter, which had not received any capital expenditure for many years and was only operating thanks to a favourable electricity deal with the state’s electricity providers. This deal was coming to an end soon, so Alcoa management’s hand was forced.

The Australian dollar is sky-high thanks to mining, which makes any of our value-adding efforts very difficult to export at inflated prices. All of the major power transmission players recognise the shift in the landscape also, and have invested in supplying conveyor equipment and drilling consumables.

The following is an excerpt from the Australian Aluminium Council…

“Australia’s world-class alumina and aluminium operations will continue to add value to Australia’s vast bauxite reserves and to underpin regional economies around Australia — provided that the international competitiveness of our industry is maintained, particularly in relation to the impact of government policy.”

What next for the Australian aluminium industry?

After getting into positive territory for the first time this year last month, the August result for the Performance of Manufacturing Index (PMI) decreased by 3.4 points, to 47.3 points. The retreat into negative territory is again a reflection of the concerns held in the Australian manufacturing industry of the continued strength of the local currency.

The PriceWaterhouseCoopers / Australian Industry Group PMI result for August clearly shows how demanding conditions are in the Australian manufacturing sector at present.

Two manufacturing sub-sectors expanded for August, whereas there were six sub-sectors that contracted for the same period.

As is almost the mantra for the Performance of Manufacturing Index every month, the gap between manufacturing input costs and manufacturing selling prices continues to grow. This statistic alone is enough to maintain pressure on an already struggling industry.

To download a two-page précis of the report, click here… PMI August 2014

All Torque Transmissions is proud to be exclusively handling the range of large DC motors from Baldor, in an agreement that has come about after many years of strategic partnership.

| Motor | Nominal | Motor | Voltage | Voltage | Current | Current | Blower | Weight | Catalogue |

| kW | r/min | Frame | Armature | Field | Armature | Field | Type | kg | Number |

| 4.7 | 1725 | B132-218 | 460 | 360 | 12.7 | 0.55 | LM3 | 118 | D4204 |

| 6.9 | 1690 | B132-219 | 460 | 360 | 18.3 | 0.97 | LM3 | 126 | D4206 |

| 11.4 | 1761 | B132-2112 | 460 | 360 | 28.7 | 1.03 | LM3 | 166 | D4211 |

| 18.5 | 1709 | B160-2513 | 460 | 360 | 46 | 1.32 | LM3 | 315 | D4318 |

| 29.4 | 1694 | B180-2810 | 460 | 360 | 71.7 | 1.95 | LM4 | 341 | D4429 |

| 33.6 | 1800 | B180-2813 | 460 | 360 | 81 | 2 | LM4 | 414 | D4433 |

| 40.3 | 1613 | B200-329 | 460 | 360 | 97 | 1.88 | LM6 | 417 | D4540 |

| 50.7 | 1645 | B200-329 | 460 | 360 | 122.6 | 1.88 | LM6 | 417 | D4550 |

| 74.6 | 1801 | B200-3212 | 460 | 360 | 175 | 2.37 | LM6 | 448 | D4574 |

| 93.2 | 1870 | B225-368 | 460 | 360 | 216 | 2.2 | LM6 | 487 | D4693 |

| 112 | 1810 | B225-368 | 460 | 360 | 260 | 2.3 | LM6 | 487 | D46112 |

| 149 | 1810 | B225-3610 | 460 | 360 | 346 | 2.2 | LM9 | 503 | D46150 |

| 187 | 1710 | B250-4011 | 460 | 360 | 427 | 3.38 | LM9 | 935 | D46187 |

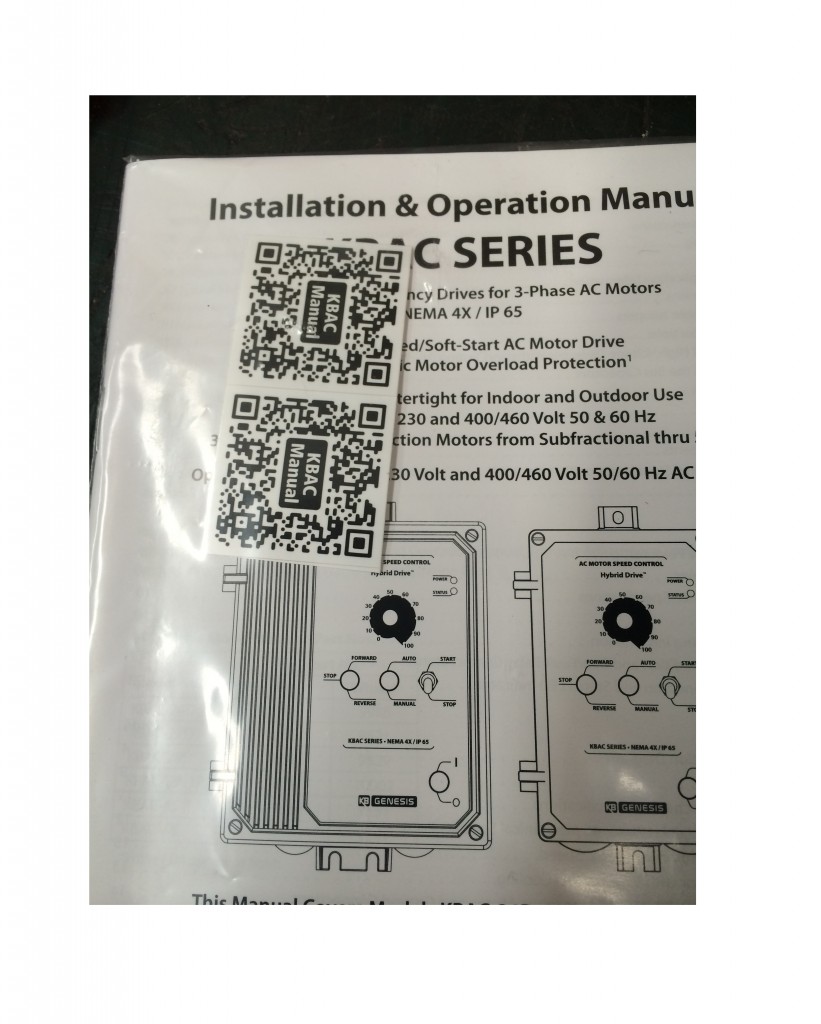

KB Electronics continues to innovate in the world of variable speed drives, backing up its world-class range of hardware with some of the best support materials available.

KB has introduced product manuals that are available to be downloaded via the use of a QR code, which smartphones can use to immediately access information on the internet.

QR codes (or Quick Response Codes) are a two-dimensional bar code that allows for the quick transfer of information. In most cases, the information is a particular website.

Having product installation manuals available for immediate download is a smart move from KB. As long-time distributors of not only KB but many brands of variable speed drives, we know that one of the first things to go missing when a new drive is installed is the hardcopy version of the manual.

Not only have KB supplied the QR code as a sticker, they have also put the code inside the drive, so that it can never go missing.

Once again, KB Electronics continues to use technology to advantage, and we are proud of our association with them.