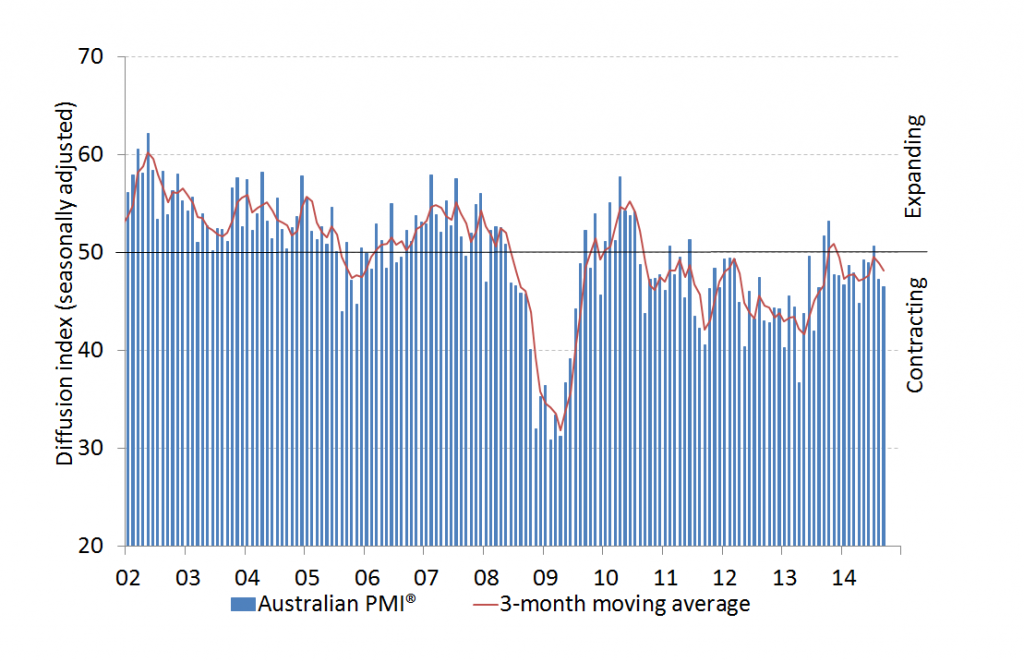

Well, I could have just copy/pasted the August 2014 result for September’s Performance of Manufacturing Index, with continued contraction across most manufacturing sub-sectors. The final result recorded was 46.5, which represents a 0.8 point reduction from August, with the three-month moving average coming in at 48.1.

Once thing that will have an impact on future results that hasn’t yet taken effect is the decrease in relative value of the Australian dollar to other currencies over the past few months.

Individual Sectors

Individual SectorsTwo manufacturing sub-sectors expanded for August, whereas there were six sub-sectors that contracted for the same period.

To download a two-page précis of the report, click here… PMI September 2014

November Drives is a part of the total All Torque Transmissions business, acquired in 2010. The core business of November Drives is Reeves mechanical belt variators.

Reeves mechanical belt variators were originally designed and developed in the United States and were for a long time the premier method of controlling gearbox output speeds across the world.

In Australia, the Reeves product range was handled by Reliance Automation (now part of ABB), with all componentry manufactured locally.

In 1996, Reliance divested Reeves, which was immediately purchased by some of the existing employees. These employees took over the manufacture of the entire Reeves range under the November Drives banner and moved to Preston, Victoria – a site which we still occupy.

In 2010, All Torque Transmissions acquired November Drives. We have proudly maintained the Reeves product and brand, with all manufactured components still made in Australia.

We have a partnership with a foundry in Melbourne’s northern suburbs for all of our cast iron parts.

We have had a long relationship with a surface technology specialist in Melbourne’s south-east, providing added value to our equipment.

We utilise local bearing suppliers and machining supply specialists for all of our sundries (although the bearings, oil seals and cutting tips are from overseas, as there is no locally-made option).

One concession to international sourcing is our variable speed belts, which are made to our standards by Gates in the United States.

This Saturday sees the 118th AFL grand final taking place at Melbourne’s MCG. Sydney and Hawthorn have been the form sides for the whole season and it is fitting that these two will do battle in front of 100,000 people and Tom Jones.

We wish everyone who is going to the game or watching it on TV (either at home, at a pub or at a friend’s barbecue) has a good time. We also would like to remind everyone that it is more than likely you will encounter a booze bus in your travels, so play it smart and have a designated driver.

The last thing anyone wants is a ruined grand final day. To remind you of what that looks like…

Bonfiglioli has long been identified as one of the premier manufacturers of wormboxes, due to both the size of the range and the quality of materials used. The wormscrew is made by a case hardened and hardened drop forging of 16CrNi4 UNI with a ground flank to increase efficiency. The wormgear is made by bronze casting G-Cu Sn 12 UNI 7013-2 cast on a spheroidal graphite cast iron hub.

For many years, the Bonfiglioli wormbox range consisted of ‘VF’ series units exclusively, where mounting position was dependent upon foot orientation. Changing the mounting position (or mounting an output flange) required the side covers to be removed and replaced. This was laborious, although did allow for any mounting position required.

Historically, these VF sizes included:

Continued product development saw the ‘W’ series introduced, replacing some of the VF sizes. The W series is identifiable by rectangular dimensions and a myriad of mounting holes.

The W series of wormboxes allows for modular mounting, which means that feet orientation no longer has to be considered. Output flanges and torque arms are also easily fitted, without needing to remove sideplates. This further expands the range of mounting options.

The current Bonfiglioli wormbox range consists of the following sizes:

Where the W series is replacing an existing VF series unit, external feet (identified as KA followed by the gearbox size) can be fitted to ensure that the shaft centre height of the replacement gearbox matches the original, as well as the original bolt hole pattern.

Some of the original Bonfiglioli VF series units that have been superseded are still manufactured for specific OEM clients, although support for the range is dwindling, with most of the focus now being directed toward the W series.

All Torque Transmissions calls upon the expertise of our supply partner, Bonfiglioli, in meeting our customers’ needs from a product perspective.

We have found that one of the main benefits of having the support of a global company such as the Bonfiglioli Group, is the technical background and resources that they can employ.

Research & Development is important to Bonfiglioli, and it shows. At the heart of Bonfiglioli’s technical expertise are their various Competence Centres, which represent the pinnacle of investment that Bonfiglioli has placed in product innovation.

Bologna, Italy

Forli, Italy

The pair of competence centres in Bologna and Forli supply the bulk of the technical innovation that filters its way throughout Bonfiglioli. Individually, they each pursue predetermined objectives. Together, they combine to make Bonfiglioli one of the foremost Research & Development power transmissions companies in the world.

Sydney, Australia

In Australia, we call upon Bonfiglioli’s Drive Service Centre (DSC) to assist with the more technical drive designs that we come across. We handle the majority of enquiries at both Braeside and Preston, although designs that push the envelope always require the manufacturer to get involved.

Bonfiglioli’s model for innovation is based on an enormous capacity for technological innovation accompanied by the continuous improvement of production and management processes. At All Torque, we not only ask for assistance from, but supply assistance to Bonfiglioli throughout the design process. This is at the core of our longstanding supply partnership.