Reeves belt replacement is a requirement, as Reeves Motodrives transmit very high torques over a significant speed range. The Reeves variable speed belt that transmits these high loads is a heavy duty belt manufactured specifically for the task. It is constructed from heat and oil resistant neoprene, with the underside of the belt notched to permit easier flexing around the pulleys, which increases belt life.

Periodically, the Reeves belt will need to be replaced. Here are instructions for belt removal and replacement.

1. Run Motodrive to the high-speed position.

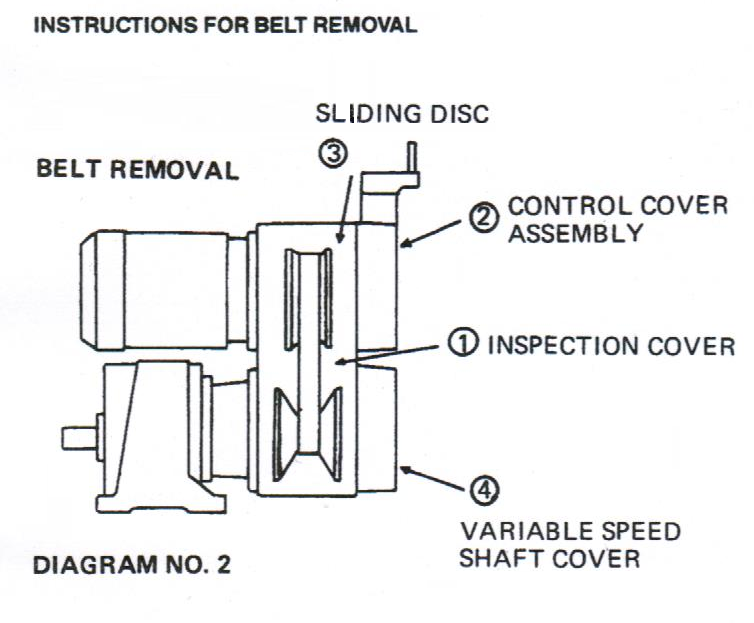

2. Remove the inspection cover (1).

3. Remove (4) screw holding Control Cover Assembly (2) and remove Control Cover Assembly from the Motodrive. Remove the Sloding Disc (3) (Thrust Bearing and Thrust Bearing Housing is attached to (3)). Leaved Fixed Disc in position.

4. Pull the loop of the belt over the end of the Fixed Disc Hub. (In some units it is necessary to remove the greaser first).

5. Remove the Variable Speed Shaft Cover (4).

6. Free the Belt from the Variable Disc (5).

7. Loop the Belt over the Variable Speed Shaft, and remover through inspection opening.

Replacement is a reversal of the above procedure. On the 20A, 30 and 40 series Motodrive, when replacing the Control Cover Assembly, care must be taken to fit the prongs of the Shifting Yoke into the lugs of the Thrust Bearing Housing. On the 600 series Motodrive, care must be taken to insert the Guide Pin into the Control Housing. In all models except 20L ensure that the shifting yoke is properly seated on the shifting nut. On the 20L, when replacing the Control Cover Assembly care must be taken to fit the Pin in the Shifting Screw into the Lugs of the Thrust Bearing Housing.

When in doubt, contact us.

Bologna, Italy manufacturer of industrial screw jacks and linear actuators, MecVel, has joined with All Torque Transmissions in offering the full range of MecVel products into the Australian market.

MecVel’s selection of heavy duty screw jacks forms the backbone of the product range, with linear actuators available for both AC and DC applications.

All Torque Transmissions distributes in Australia for MecVel, with stocks coming direct from Italy to order.

Aluminium gearbox for sizes 05, 10, 25; cast iron for sizes 50 100 200

Hardened-tempered steel wormscrew

Bronze wormwheel

Nut: bronze nut

Ball bearings

Cast iron front lock-ring

Aluminium rear pipe (HT series)

Carbon-steel (standard) ACME leadscrew

AISI 304-steel leadscrew

Ballscrew: hardened-tempered steel

The MecVel screwjacks catalogue can be downloaded by clicking on this link: MecVel Screwjacks

Twitter has been all across the news lately, with its Initial Public Offering garnering a lot of attention and generating a buzz about which other tech businesses may follow.

We think that Twitter has much to offer in the industrial world; giving businesses continual insight into world’s best practice, new product innovations and even staff movements.

If you’re already connected to the industrial B2B world through twitter, here is a short list of some of the best tweeters in Australian industry…

@manmonthly (Manufacturer’s Monthly)

@IndustryUpdate (Industry Update)

@VECCInews (VECCI)

@aus_business (The Australian)

And (of course)…

@alltorque1 (All Torque Transmissions)

Follow us to keep up to date with everything All Torque, especially our special hashtag #thetorque.

All Torque’s stocks of the KB Electronics Pentapower range of motor controls has received a massive boost, with large numbers motor drives and peripherals landing this week to bolster existing stocks held at Braeside and Preston.

All Torque Transmissions stocks the KB Pentapower range of drives in both chassis mount and enclosure mount (NEMA 1 and NEMA 4X), supported by the full offering of spares.

The KB range of controls includes the very popular KBAC range of NEMA4X drives, which range in size from 0.75kW to 3.7kW. These mostly see action in the food manufacturing and processing sector, because of their capabilities in handling washdown applications.

All Torque Transmissions has had a long association with KB Electronics. We are proud to have supplied their drives into some of the most rigorous applications possible, knowing that they will always do the job asked of them.

We are also very pleased that our partnership with KB Electronics is set to continue.

Flender Himmel Motox helical geared motors and gear units were very popular in Australia for decades, offering flexibility in mounting as well as torque range.

Structured in sizes from the 30 series through to the 181 series in foot mount, the Motox gearbox was designed for output torques ranging from 25Nm to 25,000Nm, with single, double and triple reduction options.

One of the strengths of the Flender Himmel Motox range was the modular assembly system that the German manufacturer employed, allowing all forms of configurations to be available on short delivery times. Standard components included both foot and flange mounted housings, shaft mounted housings, specialist outputs for agitators, as well as a full range of input options.

Flender was keen to ensure the Motox range incorporated as many DIN standards as possible in its design, and utilised only the highest quality cast iron for its housings and surface hardened gears throughout. Although subsequently superseded by other manufacturers in both torque capacity and dimensional compactness, the Flender Himmel Motox series was ahead of the curve during its day.

All Torque Transmissions receives many requests to supplant existing Flender Himmel Motox units with a modern-day alternative, and the original usually can hold its own in a straight line comparison between new and old.