The Bonfiglioli and All Torque Transmissions alliance started in 2001, and as a result of All Torque specialising in power transmission, our linkup has always had a focus on the technical side.

Because we are the Bonfiglioli distributor for the Victorian marketplace, All Torque Transmissions has continually utilised the technical aspects of Bonfiglioli’s available support. Chiefly among them is the Drives Service Centre (DSC), which is situated in Sydney.

Key facets of the Bonfiglioli Drives Service Centre include:

Bonfiglioli’s technical competence is renowned throughout the industrial power transmission sector. At All Torque, we use our own technical abilities and understanding of the overall marketplace in conjunction with Bonfiglioli’s backup to provide the most appropriate answer to every power transmission question.

All of the technical ability in the world would be worthless if it wasn’t supported by good business practice. That’s why we keep Bonfiglioli wormboxes and motors on the shelf in both Braeside and Preston. That’s why Bonfiglioli has invested a further $11 million in stock. And that’s why Bonfiglioli continues to increase its range of products in the Australian marketplace. In fact, Bonfiglioli’s product range is the most complete of any manufacturer represented in Australia.

All of the technical ability in the world would be worthless if it wasn’t supported by good business practice. That’s why we keep Bonfiglioli wormboxes and motors on the shelf in both Braeside and Preston. That’s why Bonfiglioli has invested a further $11 million in stock. And that’s why Bonfiglioli continues to increase its range of products in the Australian marketplace. In fact, Bonfiglioli’s product range is the most complete of any manufacturer represented in Australia.

Whether it comes to our understanding of Bonfiglioli wormbox history, our joint application engineering, or demonstrable Bonfiglioli product quality, our continued relationship with Bonfiglioli has been a great source of pride for everyone at All Torque Transmissions.

Australia’s senior leading indicator of manufacturing performance – the Australian Industry Group / PriceWaterhouseCoopers Performance of Manufacturing Index – once again recorded a negative result for February. The result of 45.4 points is a decrease of 3.6 points from January, which had recorded an increase over December, although still remained in contraction overall.

Once again of significance was the increase recorded in manufacturing exports, which have been steadily rising since the Australian dollar has been comparatively weaker against the US dollar after it’s cessation of quantitative easing.

Three sectors expanded in February, whilst the other five contracted, mimicking the January result, with exactly the same sub-sectors expanding and contracting.

The food, beverages & tobacco sector and non-metallic mineral products sector were both standout performers once again, whilst the petroleum, coal, chemicals and rubber products sector has been in free-fall for a few months in succession.

To download a two page précis of the report, click here…PMI February 2015

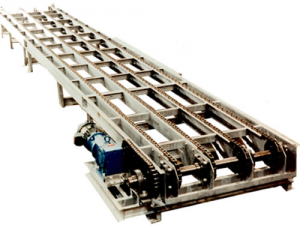

The requirements of a conveyor gearbox vary depending upon the application, with belt conveyors, chain conveyors and roller conveyors being the most prevalent in modern materials handling. Each of these three conveyor designs also have their own unique gear reducer demands.

Belt conveyors are the predominant conveyor design in use, normally used to transport material over a level area or on a slight incline. Wormboxes, bevel-helicals and even in-line helical gearboxes are fit for use.

In mining applications, shaft mounted gearbox units (such as the Bonfiglioli TA and Dodge TAII) provide excellent performance.

Parallel shaft and bevel-helical gear units are the most common conveyor gearbox for chain conveyors, which usually feature a pair (or more) of special purpose conveyor chains fitted with attachments. Product is conveyed either by the attachments or along the top surface of the chains themselves.

Chain conveyors primarily see duty in:

Roller conveyors see service where loads are long and individual rollers are driven. A standard requirement from geared motors on roller conveyors is a compact design that also offers good torque characteristics.

Parallel shaft and in-line helical gear reducers are the most popular drives utilised on roller conveyors.

In news from the wires, All Torque Transmissions supply partner Stieber is backing a human-powered vehicle at the World Human-Powered Speed Challenge held in Battle Mountain, Nevada. Team AeroVelo, comprised of professionals and engineering students from the University of Toronto, is trying to better the current speed record (which stands at 133 Km/h (83 mph), in their high speed bike named “Eta”. Battle Mountain sounds nice and steep, but the Challenge is held on a flat stretch of Highway 305.

In news from the wires, All Torque Transmissions supply partner Stieber is backing a human-powered vehicle at the World Human-Powered Speed Challenge held in Battle Mountain, Nevada. Team AeroVelo, comprised of professionals and engineering students from the University of Toronto, is trying to better the current speed record (which stands at 133 Km/h (83 mph), in their high speed bike named “Eta”. Battle Mountain sounds nice and steep, but the Challenge is held on a flat stretch of Highway 305.

Most bicycles have a freewheel which allows the wheel to rotate even when the pedals and chain are stationary. The problem that Team AeroVelo’s designers encountered was that Eta’s front-wheel-drive design could not utilize an off-the-shelf bicycle freewheel.

Early in the design process, they concluded that an overrunning clutch solution was required.

After careful research, the team contacted Formsprag in Warren, Michigan to request a Stieber Model CSK25 PP overrunning clutch, which was donated as part of Formsprag’s Student Support Program. While other clutches were considered, given the size and loads involved, the CSK was the clear choice. The clutch was press fit onto the front wheel hub body, and pressed inside of the sprocket. It is responsible for driving the wheels up to 145 Km/h (90 mph).

CSK units feature ultra-hard Formchrome® sprags which provide extra-long life, maximum wear resistance and lower maintenance costs. Formchrome sprags — exclusive with Stieber/Formsprag — are made by diffusing chromium into the surface of hardened high carbon alloy steel to form a chromium-carbide alloy.

With the help of the Stieber clutch, Team AeroVelo’s Eta speed bike achieved a top speed of 126 Km/h (78 mph) at the 2014 World Human-Powered Speed Challenge. Just think about that for a second; 126 Km/h on a flat piece of Highway 305. I don’t think that I’ve ever had my Falcon up that fast.

Here’s a quick video of the guy they’re trying to beat.

Reeves Motodrives remain a very effective means by which to transmit a variable speed in both high load and varying load applications. Far from subsiding, demand for Reeves Motodrives has actually increased over the past few years.

We are asked – a lot – for information about particular drives and applications. Instead of individually faxing pages (yes, we still have a facsimile machine here) each time someone asks, we have decided to scan one of the original catalogues and post it here.

So if you have come to this page because you have spoken with one of our sales staff who have directed you here, we would just like to say thank you for doing what we asked!

Go and make yourself a cup of tea or coffee, however, as this is a 26MB PDF file…