When considering suitable geared motors for a given application, the thermal capacity of the unit is often considered second to service factor ratings or even overlooked entirely. This is a mistake. Thermal capacity can limit selection of a gearmotor – even when it is less than the nameplate rating of the motor.

The thermal rating of a gearbox determines the power that can be continuously transmitted at a predetermined ambient temperature without resulting in the damage of the inner workings, or the degradation of the lubricant.

Most gearmotor manufacturers base their thermal capacity designs on an ambient temperature of 20 degrees Celcius, which is then adjusted based upon the duty degree of intermittence.

In Bonfiglioli’s C Series of gearmotors, units featuring more than two reductions and/or a gear ratio greater than 45:1 do not normally require the thermal limit to be checked. In these instances, the thermal rating usually exceeds the mechanical rating.

All gearbox types are subject to thermal capacities, however planetary, single-reduction helical and in-line helical units should all be checked when performing a drive design.

As the below chart for Bonfiglioli C Series in-line helicals demonstrates, 2 pole motor inputs reduce the thermal capacity of gearboxes significantly.

If there is no avoiding a drive design that does not adhere to the thermal capacity of the gearbox, external cooling can be utilised to assist in increasing capacity. The different cooling techniques usually employed are:

The method of cooling chosen is determined by unit accessibility, serviceability and cost.

Although registering an increase of 2.1 points, the Australian Industry Group / PriceWaterhouseCoopers Performance of Manufacturing Index remained in negative territory again in January.

It was a close run thing, however, with the result of 49.0 edging ever closer to neutral territory.

Three sectors expanded in January, whilst the other five contracted. This represents a departure from the standard ‘4 & 4′ result that has occurred over the past few reporting periods.

Once again, the food, beverages & tobacco sector remains very strong and an individual star performer.

To download a two page précis of the report, click here… PMI January 2015

Bonfiglioli scooped the ‘Excellence in the Application of Gears, Motors or Drives’ award at the 2014 Australian Bulk Handling Awards, or “Bulkies” as they have been freshly coined.

The All Torque Transmissions supply partner won for its collaboration with Rio Tinto and Bellingham Engineering, where 27 A-Series helical-bevel gear units were supplied to increase capacity at Rio’s rail welding facility in Karratha, Western Australia.

Held at Sydney’s Doltone House (Darling Harbour), the Australian Bulk Handling Awards is an annual independently-judged, 15 category industry gala that rewards achievement in various bulk handling associated domains. For 2014, the categories included:

For 2014, finalists in the Excellence in the Application of Gears, Motors or Drives category were:

The 2014 project win does not represent the first time that Bonfiglioli has won this award, having taken out the top position numerous times previously, with the last win back in 2012.

As we seem to do every year, All Torque would like to congratulate Bonfiglioli for once again taking out the top award in the industry.

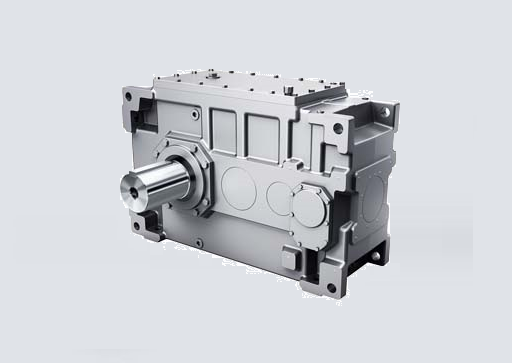

Flender manufacturers the SIG (standard industry gear) and SIP (planetary) gear unit ranges. All Torque Transmissions distributes the entire range, with delivery ex Europe.

Flender has developed 25 sizes across seven types of both helical and bevel-helical gear units. In addition, Flender gear units come with a nominal power rating of up to 3900kW for the helical series.

At All Torque, we have seen Flender gear units used extensively in the paper manufacturing and recycling industries, as well as some larger conveyor drives. According to Flender themselves, applications extend to:

As with most helical gear units such as Flender’s SIG and Bonfiglioli’s HDP, mounting positions are flexible, allowing for their fitment into more and more applications.

Just to remind everyone, we gave our website a birthday back in 2013. We thought that we should share some information about the products that we supply – as well as the industry in general, figuring that the knowledge is better when it’s available to everyone than just in our heads!

Our new computer was obviously slow and tedious, but still a big step from what we had. As the above photograph shows, the steering wheel was put to good use.

These were the most popular posts from our ‘The Talk’ section of the All Torque website in 2014.

Bonfiglioli EP Series Gearboxes