One of our product partners – Warner Electric – has asked us to share this short video, outlining exactly what their range is capable of.

Sales Director Mathieu Ruault is very precise in his efforts in keeping it this interview short, as it would take us MUCH longer to describe the benefits and advantages of their vast range!

This video comes courtesy of Altra Industrial Motion (which encompasses the Warner brand) and was recorded at Hanover Messe 2013.

Warner Electric leads the world in the design and development of electro-magnetic clutches and brakes, having pioneered the technology over 70 years ago and maintaining market supremacy ever since.

Warner’s range of electromechanical actuators are available to meet varying design demands, from light and general duty through to heavy duty applications.

All Torque Transmissions are distributors for the full range of Warner Electric equipment, keeping a range in stock in Braeside as well as dealing directly with the source. In addition, one of our main capabilities is the ability to service and overhaul existing equipment, helping to extend service life.

Just to remind everybody that All Torque’s Northern Branch is situated in Preston, having moved there from Thomastown in 2010.

We service all of the northern and western suburbs of Melbourne from our Preston facility.

We have still had some customers sending gearboxes for repair to our old address in Brand Drive. For the record, our Northern Branch address is:

All Torque Transmissions

6 Reserve Street

Preston VIC 3072

Ph: 94801566

Fax: 94804859

We ask that all customers and suppliers update their records to avoid annoying the poor courier companies who end up getting the run around when they go to our old place.

Sometimes, there is only one answer to a problem.

When customers come to us with issues in power transmission, there are normally a few ways to solve the problem. Sometimes, there is only one way, although the one way may involve utilising disparate components. So it was, when we came up with this SEW / SITI / CMG combination.

We used an SEW-Eurodrive in-line helical gearbox, fitted with an output flange which was sized to bolt straight in to the existing application. Getting this sizing correct meant that the new unit fitted directly as a bolt-in replacement, which alone saved hours of fabrication and labour.

SITI

SITIThe SITI MK series variator is able to deliver a reduced input speed to the gearbox, controlling the overall speed of the unit, whilst maintaining optimum motor speed. The application precluded running an electronic variable speed drive, so the SITI variator alternative proved to be extremely successful.

CMG provided the electric motor for this one, bolting directly into the SITI variator. Having components all running IEC flanges makes things a lot easier!

We are distributors for a variety of brands and manufacturers, all with specific features and benefits. However, we do not limit ourselves to only the brands we officially distribute if it means our customer service levels will suffer.

“Get the customer up and running”, especially in a breakdown situation, is our maxim at All Torque Transmissions.

2014 will see some turmoil in Australian manufacturing overall, which leads to extra issues for the mechanical power transmission supply industry.

The plight of the Australian automotive manufacturing sector is well documented, with a steady stream of evacuees taking flight since 2008 (Mitsubishi, Ford, Holden). As is also well documented, these businesses were taxpayer-subsidised to some degree (like most car makers in the world), so their exit has been received with mixed feelings.

One thing that hasn’t been so well documented is the outcome of the closures on the significant amount of automotive parts suppliers, that constitute far more workers than the car manufacturers themselves. The Federation of Automotive Product Manufacturers (FAPM) alone has 80 members, which rely on the critical mass of business from more than one automotive customer to remain viable.

One thing that hasn’t been so well documented is the outcome of the closures on the significant amount of automotive parts suppliers, that constitute far more workers than the car manufacturers themselves. The Federation of Automotive Product Manufacturers (FAPM) alone has 80 members, which rely on the critical mass of business from more than one automotive customer to remain viable.

As it stands, Toyota remains the only manufacturer in Australia from 2018, although doubts about their future are also recognised. Obviously, Toyota’s departure is the absolute end of the road for an industry which once contributed 2% towards total GDP on its own.

With a change of focus away from the automotive manufacturing sector, the underlying question remains: What sector should the focus move towards?

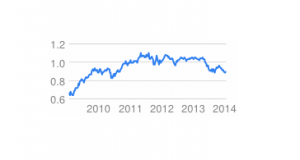

As the fifth most traded currency in the world, the Australian dollar reflects the overall strength of the economy. Overall, the Australian economy has been on a sustained high thanks to the boom from mining sector investment, which has resulted in relatively high interest rates and added currency attraction.

An attractive currency has brought about mixed blessings for those in the manufacturing sector. For one thing, the price of exporting goods is higher than it otherwise would be, which makes local manufacture less sustainable. Obviously, imported competition is also more cost-competitive, resulting in a two-edged sword for the locals.

It’s not all bad news. Input costs (apart from labour and utilities) tend to come down with the higher dollar. Nearly all power transmission products that are available in Australia are imported, which means that pricing for these items remains stable.

The sustained mining infrastructure boom, a widening gap in the sell price to wage cost ratio and the diminishing engineering focus in schools have all played a part making the manufacturing sector less attractive to new employees. Not only that, the learning curve for power transmission industry newcomers is so steep that many leave before they have a chance to get settled.

This problem is not unique to Australia, however, as the US-based Power Transmission Distributors Association (PTDA) has recognised the need to increase industry attractiveness. To do this, they have come up with the University of Industrial Distribution, and a series of four-day courses.

At All Torque Transmissions, our ongoing commitment to training sees us utilising the knowledge base that we have with our existing staff, augmented by formalised training from our supplier partners.

Are you get what you’re paying for? Many reputable power transmission brands (including Motovario and SEW-Eurodrive) have long been victim to imitations passing themselves off as the real thing. As the copiers become increasingly brazen, the risk exists that even more brands are going to be exploited.

Manufacturers in the bearing industry are fighting back, with the WBA’s Stop Fake Bearings campaign, which has helped to uncover numerous pass offs being manufactured on a commercial scale. Members of  the geared motor industry have yet to form an alliance to curb the growing trend of ‘reverse engineering’, but this is something that is surely not too far away.

the geared motor industry have yet to form an alliance to curb the growing trend of ‘reverse engineering’, but this is something that is surely not too far away.

No industry remains in the same state all of the time. It is through change that development takes place. 2014 is going to see a fair bit of ‘development’.

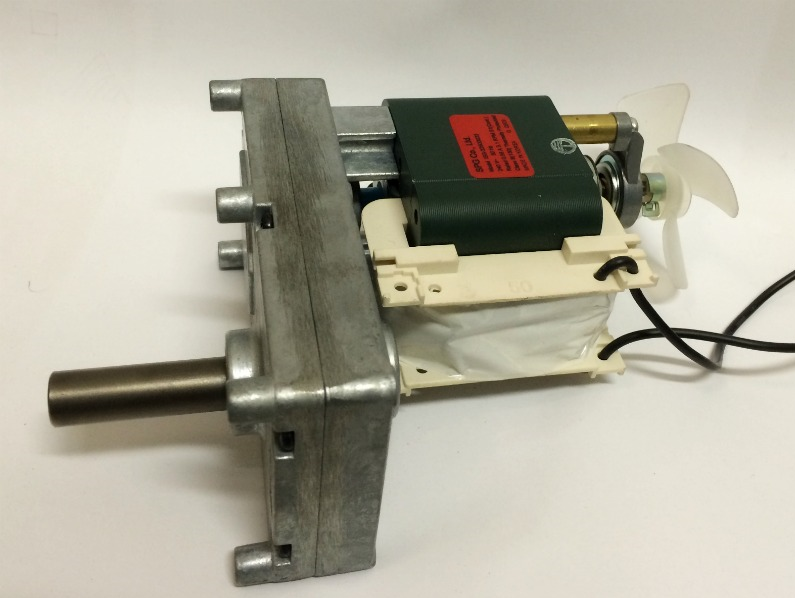

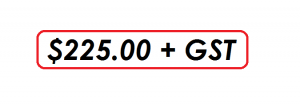

All Torque Transmissions markets a range of commercial-quality BBQ spit motors for heavy duty applications.

Manufactured in Korea by SPG, our BBQ spit motors (more precisely known as shaded pole induction geared motors) are not the ‘economical’ version that is popular in hardware-chain stores.

Also in the range is a stainless steel motor cover, designed specifically to suit the SPG spit motor.

Stocks are available at both Braeside and Preston. Larger enquiries should be directed to our Braeside office.