Charles and Hunting geared motors and variable speed drives were – for a long time – a staple of the Australian industrial landscape.

The Charles and Hunting range included:

Part of the strength of the C & H range was the dual-reducer gearmotor, which enabled very high reductions in a reasonably compact unit. Indeed, the H3R in-line helical-spur reducer was available with an overall ratio of up to 107000:1!

Nowadays, extremely high ratios are normally achieved by using a planetary gearbox and matching it with either a bevel-helical or shaft mounted reducer.

Charles and Hunting may be most well known for their inline variators. With 6:1 variation up to 0.37kW and 5:1 variation to 4kW, the range was both substantial and near-ubiquitous in Australian manufacturing for decades.

Charles and Hunting’s factory was situated in Wangara Road, Cheltenham, before relocating to 79-81 Cochranes Road, Moorabbin (now occupied by Fontelle.)

Charles and Hunting’s factory was situated in Wangara Road, Cheltenham, before relocating to 79-81 Cochranes Road, Moorabbin (now occupied by Fontelle.)

Many staff who have been involved in the industrial power transmission industry have dealt with Charles and Hunting in one way or another over the years, and we salute the position that C&H occupied.

Italian planetary gearbox manufacturer Bonfiglioli has increased the flexibility of its Trasmital planetary gearbox range, making it easier to disassemble the units for periodic maintenance.

Envisaged for applications such as long travel drives, conveyor drives, lifting and hoisting, Bonfiglioli’s product development has spawned two new innovations:

Hollow Shaft With Key

Hollow Shaft With KeyA totally new output version labelled the FDK is available in Trasmital sizes 300 to 310. The FDK features a hollow shaft with two keys (@ 120 degrees), which helps to deliver rated torque and maximum torque transmission.

Also featured is an axial locking ring with threaded holes to assist with shaft mounting.

Splined Hollow Shaft

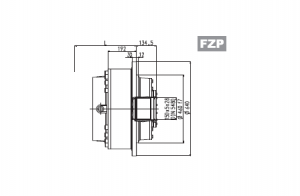

Splined Hollow ShaftAnother new output version labelled the FZP is available in Trasmital sizes 311 to 325.

Features of the FZP output include:

Replacing the existing shrink disc configuration above size 315, the new set up is a product extension of the solution already featured in the Trasmital sizes 323 and 325.

With 259 million registered users worldwide and 6 million in Australia alone, LinkedIn continues to represent the pinnacle of online business networking.

All Torque Transmissions has a page on LinkedIn, which details some of our product range as well as some of the more business-oriented posts from our website and blog.

If you are one of the 6 million Australian LinkedIn users, you can follow us on the company page by following this link.

We look forward to seeing you there.

All Torque Transmissions supplies the full range of WEG Exd E2 flameproof electric motors, from 0.37kW to 315kW.

WEG electric motors for hazardous areas include Exd, ExnA, Extc and Extb. All are high efficiency and MEPS compliant.

The WEG Exd electric motors range starts in 90 frame and goes all the way through to 355 frame, in foot, foot/flange and flange mount, with 2, 4 and 6 pole speeds off the shelf. 8 pole and 10 pole motors are also available upon request.

WEG Exd electric motors are suitable for usage with VSDs, although derating may be required subject to application.